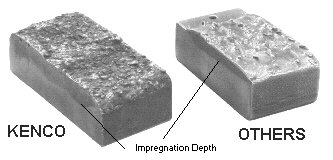

Tungsten Carbide Impregnation is an exclusive Kenco Engineering manufacturing process. At the Kenco factory, a job-suitable parent metal is melted to a depth between .250" and .375". While in a liquid state, crushed Kenco tungsten carbide chips are dropped into the molten puddle. The wear part is then allowed to cool, solidifying the tungsten carbide deep in the parent metal. After impregnation, all Kenco wear parts are mechanically flattened to exacting tolerances.